Since its origins of basic protection, pharmaceutical packaging has evolved immensely alongside treatments and medicines. Today, pharmaceutical packaging stands as a testament to innovation and progress in the medical sector.

In this blog, we take a look at the role of pharmaceutical packaging over the years and how it’s embraced cutting-edge solutions to meet today’s challenges.

1. The early years of basic pharmaceutical protection

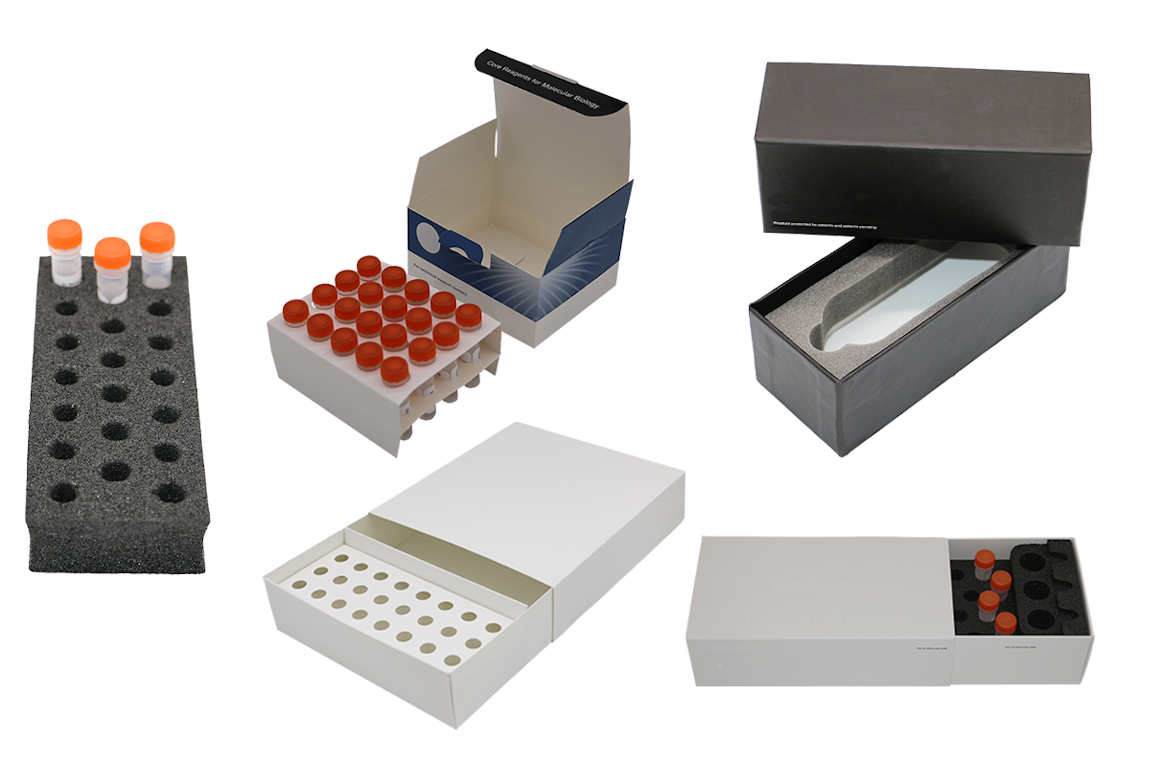

During the early years of pharmaceuticals, the primary goal of packaging was to provide fundamental protection for drugs. Glass bottles and vials emerged as the standard containers for storing medications, serving as a barrier against contamination, light, and moisture. The utilisation of glass containers played a critical role in maintaining the stability and integrity of drugs, shielding them from external elements that could otherwise compromise their effectiveness.

While glass bottles and vials offered a reliable means of protection, they were not without their limitations, especially without secondary packaging. The fragile nature of glass made these containers susceptible to breakage, posing potential risks to both patients and healthcare providers. Additionally, glass containers presented challenges in accurately measuring precise doses, often requiring the use of additional tools or devices.

These limitations prompted the industry to seek innovative solutions to address these shortcomings and enhance the functionality of pharmaceutical packaging. But before we explore how the packaging industry evolved to support medical products effectively, let’s take a look at how pharmaceutical packaging used to be in a little more detail.

Ancient times

In ancient civilizations such as Egypt, Greece, and Rome, the history of pharmaceutical packaging dates back to the use of natural and locally available materials. Medicines were often stored in containers made of clay pots, animal bladders, and glass bottles. Clay pots provided a reliable option for storage due to their ability to shield medicines from environmental factors such as moisture and even pests. Animal bladders were utilised as pouches for holding liquid medications, as they were sturdy and prevented evaporation or contamination. Glass bottles, though relatively more advanced, were employed by societies like Rome. The non-reactive nature of glass preserved the medicinal properties of the contents. These early containers were often sealed with corks or other natural stoppers to maintain the integrity of the medicines.

Middle ages

During the Middle Ages, the practice of using various natural materials for pharmaceutical packaging continued, but with an emphasis on portability and preservation. Apothecaries and herbalists utilised fabric pouches made from materials like linen or silk to store medicinal herbs and substances. These pouches were convenient for carrying and offered protection against light and moisture. The pouches were sealed using wax, strings, or elaborate knots to ensure the safety of the contents. Animal skins, such as parchment or leather, were also used as packaging materials during this period. These skins were durable and provided an additional layer of protection for medicines.

Industrial revolution

The Industrial Revolution (during both the 18th and 19th centuries) marked a significant shift in pharmaceutical packaging through the adoption of mass production techniques. This era saw the manufacturing of standardised glass bottles and vials, replacing hand-blown glass containers. The standardisation ensured consistency in shape and size, making it easier to fill, store, and transport medicines. Glass bottles were sealed primarily with corks, chosen for their ability to create a secure barrier against air and moisture, increasing the stability and shelf life of pharmaceutical products. This period's advancements paved the way for modern pharmaceutical packaging methods and set the stage for further innovations in the industry.