This ultimate guide explores the various aspects of commercial pharmaceutical packaging, from its all-important protective functions to its role in fostering patient engagement.

Commercial pharmaceutical packaging ensures product protection

Commercial pharmaceutical packaging is carefully designed to safeguard medicines from a wide range of external factors that have the potential to compromise their quality, potency, or safety. These key considerations ensure that medications reach patients in optimal condition, maintaining their efficacy and integrity throughout their shelf life. These considerations include:

1. Environmental Factors

- a) Moisture and Humidity: Exposure to moisture can lead to chemical degradation, loss of potency, or microbial growth in medications. Pharmaceutical packaging materials with moisture barrier properties, such as blister packs or moisture-resistant containers, help protect against moisture intrusion.

- b) Light: Certain medications are sensitive to light and can undergo photochemical reactions, resulting in degradation. Light-protective packaging, such as amber-coloured bottles or opaque blister packs, shield drugs from harmful UV rays, preserving their stability for safe consumption.

- c) Temperature Control: Temperature fluctuations can negatively impact the effectiveness of pharmaceuticals. Packaging solutions may incorporate insulation or temperature-resistant materials to prevent exposure to extreme heat or cold during storage and transportation.

- d) Oxygen Permeability: Oxygen can cause oxidation reactions, leading to the degradation of drugs. Packaging materials with low oxygen permeability, such as aluminium foil or specialised films, help minimise exposure to oxygen, maintaining the product’s stability.

2. Physical Protection

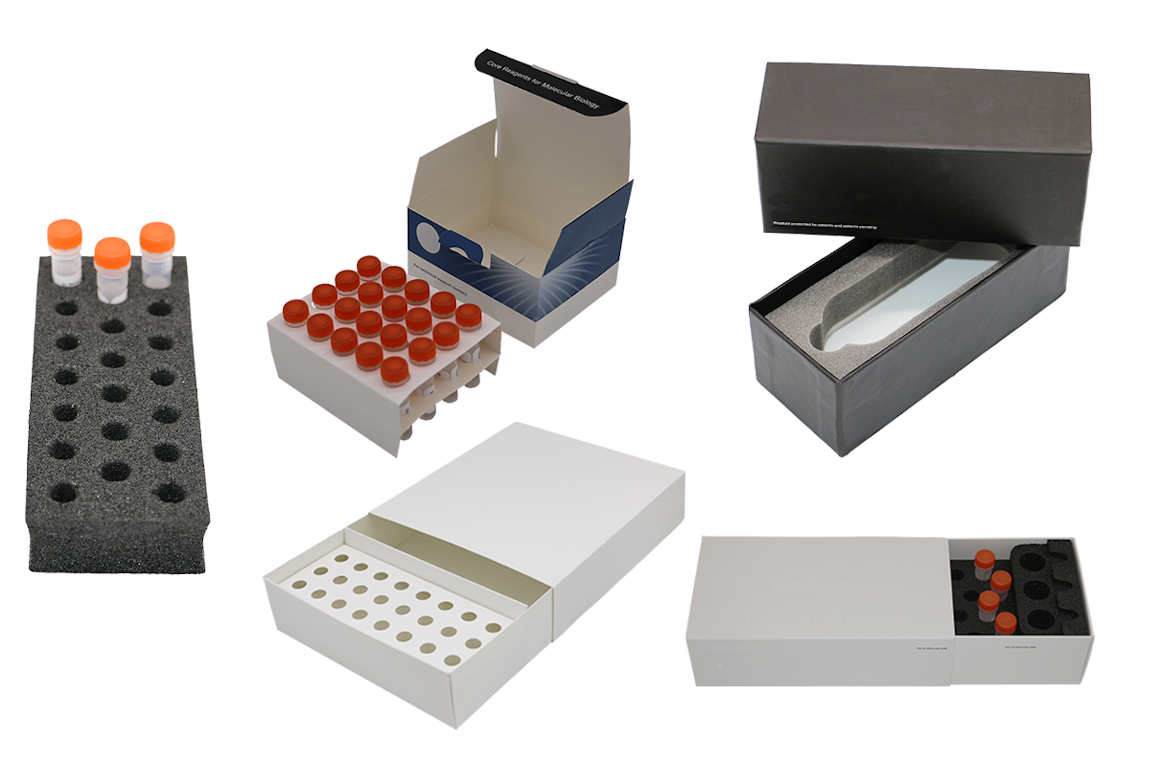

- a) Impact Resistance: Pharmaceuticals can be vulnerable to damage during handling, shipping, or accidental drops. Packaging should be designed to withstand such impact and provide cushioning or shock-absorbing properties to protect the integrity of the medication. Impact labels can be used alongside a protective packaging solution to not only deter rough handling, but record and monitor damage to hold responsible parties accountable.

- b) Vibration and Compression: Excessive vibration or compression can result in physical changes or formulation issues in medications. Commercial pharmaceutical packaging should minimise the transmission of these external forces to maintain the integrity of the product.

- c) Tamper Evidence: Tamper-evident packaging helps identify whether a product has been compromised, ensuring the integrity of the medication. Primary pharmaceutical packaging features like induction seals, breakable caps, or shrink bands offer visible evidence of tampering.

Tamper-evident packaging solutions can also be integrated into the outer (secondary and tertiary) packaging. With the likes of tamper-evident adhesive tape, as well as custom made boxes that show damage upon opening, there are many ways to help deter and detect the tampering of commercial pharmaceuticals.

3. Contamination Prevention

- a) Microbial Contamination: Packaging materials should be selected to prevent microbial contamination, which can compromise the safety and sterility of medications. Sealed and sterile packaging, such as ampoules or vials, helps maintain the integrity of injectable drugs.

- b) Chemical Contamination: Packaging should be free from chemicals that could leach into the medication and cause adverse reactions. Strict quality control measures ensure that packaging materials do not introduce harmful substances that can interact with the drug formulation.