Did you know that it was estimated by the Ellen MacArthur foundation that there could be more plastic than fish in the ocean by 2050? A circular economy approach is a reliable solution to solve the plastic pollution problem. Therefore, many businesses are starting the switch to a more sustainable ‘circular economy’ structure to reduce their plastic waste. In this article, we will discuss circular economy and how it can benefit your business.

How can circular economy benefit your business?

Concerns over sustainability and the environment is at the forefront of consumers’ minds. People are becoming more aware of the packaging systems they use, such as the mainstream linear system, and how it can be a detriment to the environment.

What is a circular economy?

Firstly, what is circular economy? Circular economy is an alternative to the ‘make, use, dispose,’ system of traditional linear economy (raw materials used to make packaging and then once consumed the packaging is thrown away). With circular economy, resources are kept in use for as long as possible whilst the maximum value is being extracted from them, then products and materials are recovered and regenerated at the end of each service life.

The importance of circular economy

Mainstream packaging today is still unsustainable because the ‘linear’ approach to packaging remains the most popular system. However, in circular economy waste is reduced to an absolute minimum, making it good for both business and the environment as it uses resources more efficiently.

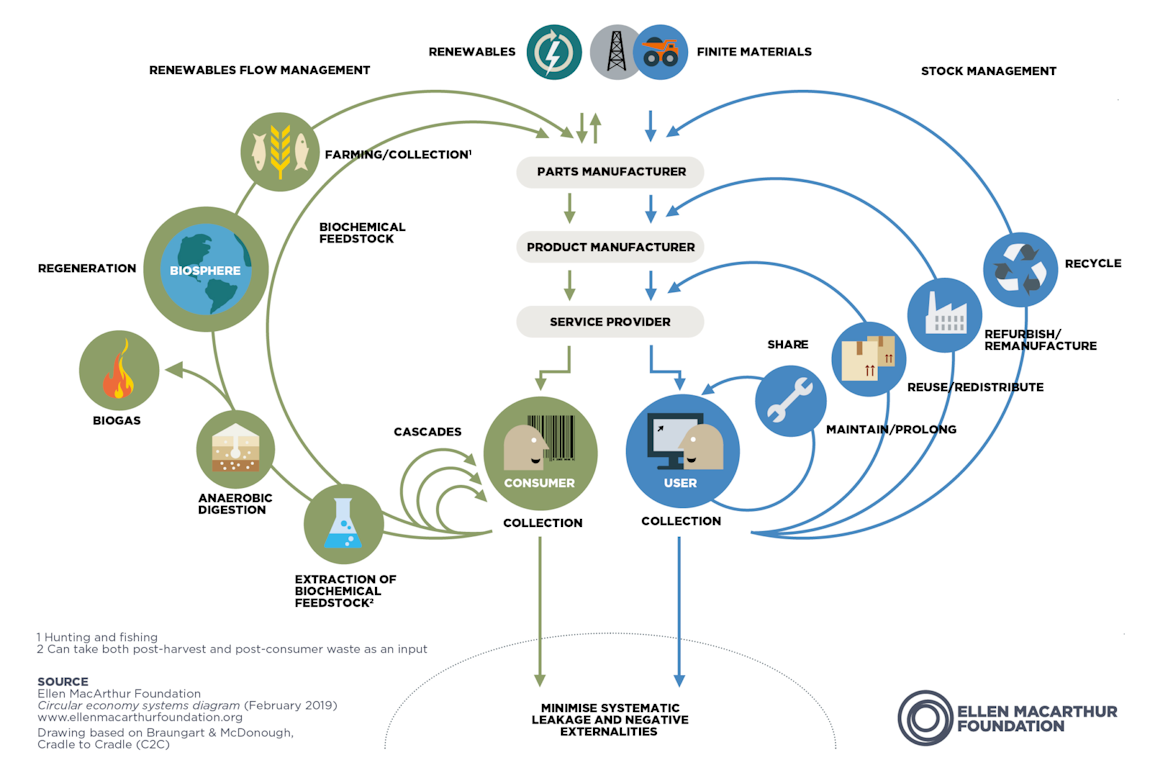

The diagram above shows how circular economy works:

- Use: making products that can last a lifetime, ideally the use phase should be for as long as possible.

- Reuse and Repair: offering options to reuse a product or alternatively offering repair options.

- Return or recycle: involves switching to a service model where you can be the owner of products, remaining responsible for the return and recycling.

- Take and make: when companies start investing in circular economy, this is often the starting point. Includes sourcing of recycled materials and reduction of resource consumption in the production process.

- Waste and Disposal: when no other options are left, products are disposed.

Upstream and Downstream Innovation

When companies invest in circular economy, they often start with sourcing of recycled materials and reduction of resource consumption in the production process. Although a good start, creating a product with 80% recycled materials still ending up on a landfill is still not good enough, that is why it is important to use the two types of innovation methods in order to achieve a circular economy:

- Upstream Innovation: Rethinking products and services at the early design stage. Including developing new materials, business models or product designs.

- Downstream Innovation: Developing new collections, sorting, and recycling technologies.

Upstream innovation is all about preventing the waste from being created in the first place, and downstream innovation is the process of turning the inventions and processes into economic value.

How to start your upstream innovation:

If you are looking to switch to the circular economy approach, you will need to not only rethink the packaging itself but also the product and the business model, in order to ensure no waste is produced. Some of the ways you can start your upstream innovation:

- Rethink your packaging: Look over the packaging design concept, format, components, and material choice to make sure it provides the same packaging function without the waste. For example, using recyclable packaging or edible or dissolvable material.

- Rethink your product: Innovating product formulation, concept, shape, and size to change packaging needs whilst still maintaining and improving user experience. This can include changing from a physical product to a digital product or a liquid to a solid product.

- Rethink your business model: Innovation at the system design level, looking at the delivery model, supply chain, location of production and revenue streams. For example, selling products in refillable or returnable packaging, instead of using single-use packaging.

The Elimination process

Without elimination, achieving a circular economy will not be possible. To achieve a circular economy, the amount of material circulated needs to be curbed. This means elimination is more than just a ban on straws and plastic bags. Many businesses are realising that a range of packaging items in a variety of their applications are unnecessary and can be removed while still maintaining and enhancing user experience.

There are two different approaches to the elimination process:

- Direct Elimination: packaging that does not serve an essential function and so is directly removed. This can include removing secondary plastic wrapping from multi-buy items such as canned food and beverages, removing tear-offs from water bottles and jars, or removing any unnecessary plastic film.

- Innovative Elimination: packaging that does serve an essential function and so is indirectly eliminated through innovation. This includes edible coatings for fresh produce that extend shelf-life, eliminating the need for the packaging.

Reusing materials can also help to cut costs, optimise operations and further improve user experience. When the packaging can no longer serve its function, the material should then be circulated through recycling or composting.

Why should your business join a circular economy?

- Improves resource security: a great starting point is working out which materials are critical for your business and which are most at risk. Switching to safe, sustainable materials provides resource security and price stability.

- Reduces climate disruption: Local and distributed manufacturing can reduce the risk of disruption from geopolitical issues to global trade tensions or climate change.

- Increases revenue and profit: New by-products made from your recovered waste can generate new market and sales. Create new revenue streams by including repairs, manufacturing, reselling, consumables and special tools in your offer.

- Form stronger relationships: relationships with suppliers, employees, local communities, and shareholders are also strengthened through circular, regenerative strategies.

- Build stronger reputations: circular economy approaches allow you to build stronger brand reputations. Brands selling bad quality products such as using non-recyclable packaging have started to be criticized on social media, so it is important to maintain brand integrity.

By moving away from traditional linear economy and using the circular economy approach instead, your business can begin to thrive like never before. As a certified B-Corp, this topic is close to our heart. Thus if you want to learn more about sustainable solutions or want to partner up to create a circular economy, give us a shout.