While Gel packs and dry ice both keep your packages cold, they do so at different temperatures and different lengths of time. This is why it is important to establish which option would be best for you and your products. In this article, we will discuss the benefits of dry ice vs gel packs and guide you towards the best solution.

Dry Ice vs Gel packs: which is better for your business?

Temperature-controlled packaging is crucial for shipping sensitive goods such as chilled and frozen food products or pharmaceuticals. But which method is best for your industry and its products?

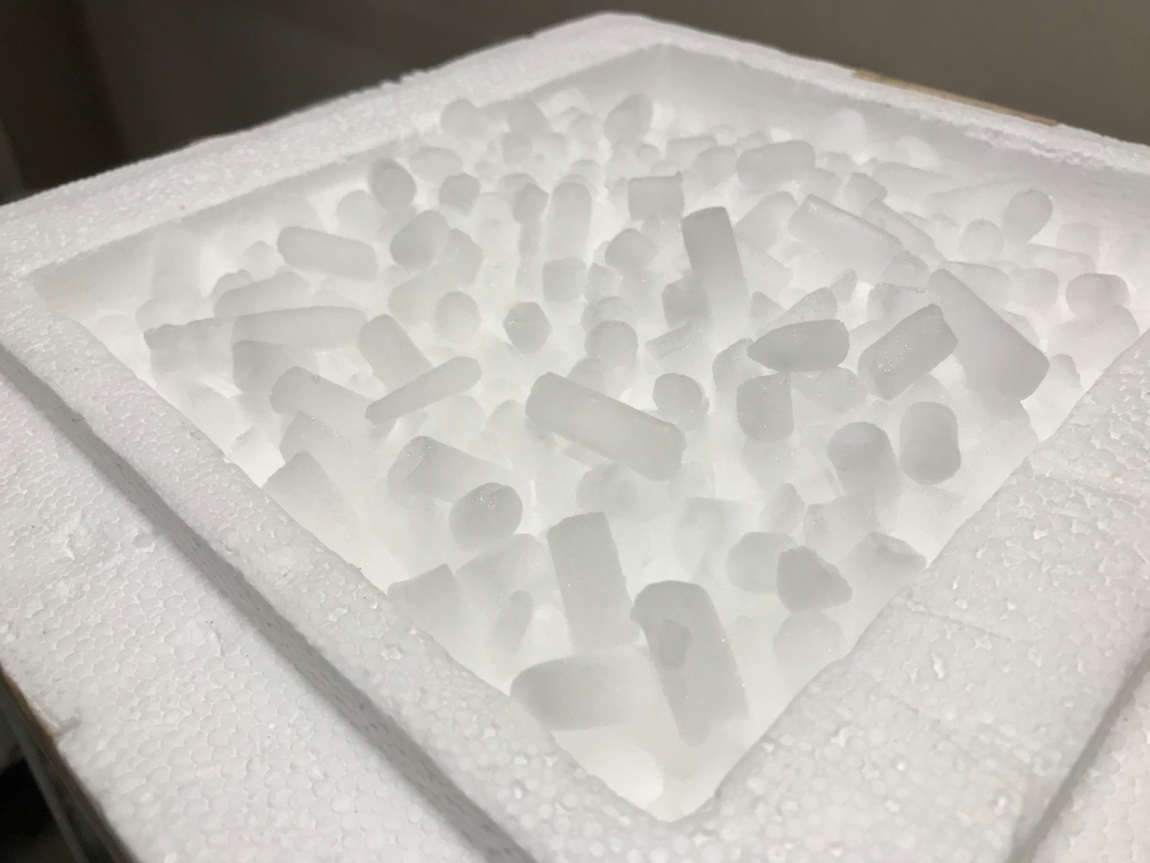

Dry Ice

Firstly, did you know that often people assume dry ice is another form of water when actually the substance is a solid form of carbon dioxide sitting at -79 degrees Celsius? This is why dry ice is the best choice for any products you want to keep frozen as it stays much colder than gel packs, and for a much longer time.

The benefits

- Dry Ice lowers the product temperature so that it stays frozen for longer, making it most suitable for food products such as ice cream, frozen meats and seafood.

- When dry ice thaws, it does not turn into liquid it just sublimates or turns back into gas, this means you do not have to worry about your products getting wet.

- Perfect for long transport journeys, dry ice will keep your food products frozen solid until they arrive at the final destination.

- It is safer for the environment as dry ice turns into CO2 gas and completely disappears so there is no secondary waste.

- Dry ice can be more cost effective as you do not have to worry about reusing gel packs.

It is important to note that dry ice should not be used with products that are sensitive to freezing, including live seafood, fresh food or certain pharmaceuticals. Any food items shipped with dry ice should always be completely sealed so that the dry ice does not change the texture or taste of the product.

Dry ice can be dangerous to handle if you touch it without the right protection. For example, dry ice must never be handled with bare hands. It is always important to add the right safety and hazard labels to your package before you mail it full of dry ice. Overall, dry ice is a very helpful tool when handled correctly.

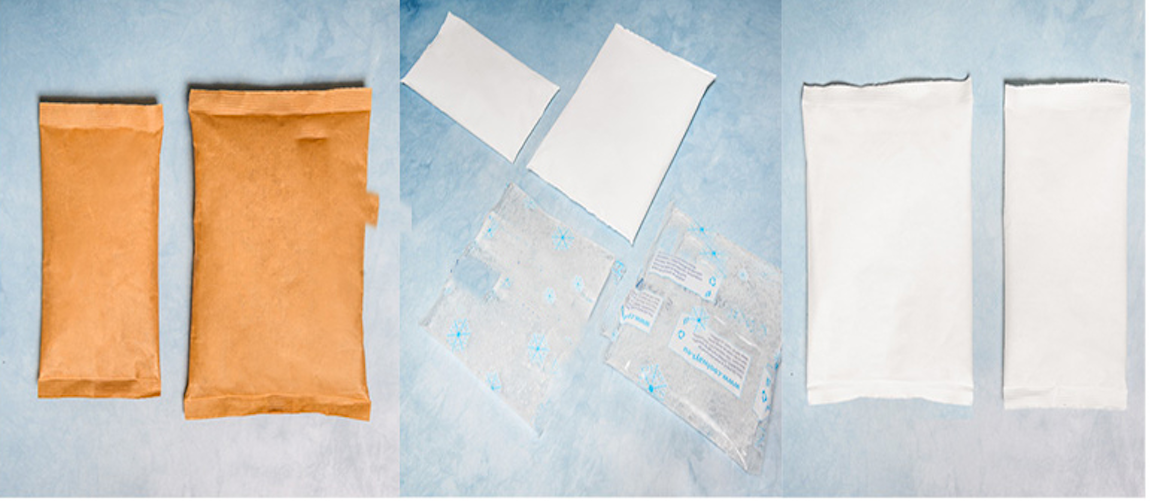

Gel packs

The first re-usable gel pack was developed in 1971, and was described as “a folding, wallet-sized plastic pouch containing a special liquid that stays either hot or cold for a long time.” It was designed to keep food and drinks temporarily cold, as well as for uses on body injuries. Today, gel packs are still the best dry ice substitute for products that must not be frozen solid, as they will not result in temperature damages. Gel packs usually maintain a product at 2 to 8 Celsius depending on the weight and starting temperature.

The benefits

- The best option for quick deliveries and for products that do not need to be frozen solid such as fresh produce, dairy products, baked goods, chocolate, and some pharmaceuticals.

- As a single item, gel packs are easy to use and good for storage.

- For sensitive pharmaceutical items, gel packs will not contaminate the product unlike dry ice.

- They can be added at room temperature during the winter to help prevent sensitive products from freezing.

- Gel packs require no special handling safety guidelines unlike dry ice.

- Perfect option for meal kits and your customers can re-use them for other activities such as picnics.

Gel packs from Swiftpak

- No sweat gel packs: keep your moisture and temperature-sensitive products dry and chilled with their non-woven outer layer reducing condensation.

- Eco Friendly Gel packs: made from kraft paper, they can be disposed of through the normal waste stream and provide less pollution than the normal variety. The kraft paper absorbs some of the condense which can appear, keeping your product dryer than normal gel packs.

- Segmented gel packs: designed to better cover your products and produced to ensure conditioned transportation.

To decide which temperature-controlled packaging solution is best for you, make sure you know the temperature your product needs to maintain during transit. Dry ice is the better choice when shipping food products that need to be frozen solid, whereas gel packs are more beneficial for shorter journeys such as same day or overnight shipping of more temperature-sensitive products like pharmaceuticals. If you need further information on what is the best option for you, contact our sales team today and we will be happy to help.